Home > Laser Crystal Technology > Laser Crystal Processing

Laser Crystal Processing

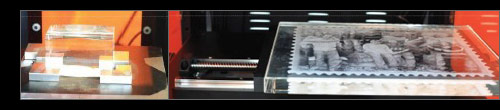

2D, 3D laser inner engraving machine can engraving 3d picture in the crystal very quickly. Take a 3D picture with 3D camera. Process it in computer to form 3D portrait, which is compatible with laser engraving machine.

Steps of 2D or 3D Laser Crystal Processing

3D Camera Head Image > 3D Camera > Laser3D Software Generate Point Cloud > Machine Machining > 3D Laser Crystal Final Product

Digital Camera Photo > Adobe Photoshop Software Design > Laser3D Software Generate Point Cloud > Machine Machining > 3D Laser Crystal Final Product

2D Logo Picture > 3D Max Software Design > Laser3D Software Generate Point Cloud > Machine Machining > 3D Laser Crystal Final Product

2D Picture > 3D Max Software Design > Laser3D Software Generate Point Cloud > Machine Machining > 3D Laser Crystal Final Product

Burning Crystal to Draw Points

The points are tiny (.1mm) fractures created by a focused laser beam from 3d laser engraving machine. The conical beam, with a focal length of about 3", shines into the crystal (glass) without damaging it except at the focal point. At that one point, concentrated energy heats the crystal (glass) to the cracking point, causing a microfracture.

To draw more points, the laser is pulsed on and off. To make the beam move between points, it's reflected from a mirror that is repositioned between pulses. The mirror is moved by computer-controlled motors, so many points can be drawn with great speed and accuracy. A typical design might use several hundred thousand points, or half a million isn't unusual in a large block, each placed with .001" accuracy.

Point-Cloudy Image

Point-cloud image consists of abundant small points which are created by the special point-cloud converting software from a common two dimension or three dimension image. These points shall be engraved by laser machine according to the array order one by one. Each point will be burnt inside the transparent material, all the burnt points form the engraved image inside the crystal cube.

Image or Portrait Design

All designs are made entirely of points because the process offers no way to draw continuous lines or surfaces. However, with small enough points it's possible to arrange them into convincing curves, surfaces and volumes.